Share your journey

We would like to thank D’Amico for taking the time to share their story. We would love to hear from our other Members about their decarbonisation journey. Please contact Mark Smith to find out more.

This is archived. This content was originally published on nepia.com or standard-club.com and will no longer be updated. Please check our live news area for all our latest updates.

The voyage to decarbonisation presents organisations within the maritime community many unique challenges, where no ‘one size fits all’ solution exists. In the spirit of mutuality, North Member d’Amico kindly shares with us their experiences following successful biofuel trials; carried out jointly with Trafigura, engine makers and classification societies.

The certification of its entire fleet of LR1 product tankers allowed their vessels to permanently operate on a B30 biofuel blend. B30 represents a 30% mix of biofuel derived from renewable feedstock, which results in reduced CO2 emissions when considered on a life cycle analysis (well to wake) basis.

d’Amico carried out a detailed risk assessment before conducting trials with B30, identifying the different hazards typically associated with biofuel blends. The mitigation actions put in place several protocols in handling and burning the biofuel, including but not limited to:

Fuel testing protocol

Change over protocol from conventional fuel to the B30

Sea trial protocol

NOx protocol measurement

Post-trial inspection protocol

Trials were conducted without any adjustment in engine parameters and without any operational issues. Furthermore, no technical modifications were carried out on the engines tested, therefore confirming B30 is a ‘drop-in’ fuel solution.

Lubricating oil providers and engine manufacturers advised that there were no specific requirements on lubrication when burning B30, but advised:

Careful selection of the cylinder oil injection rate – matched with the fuel sulphur content

Acid number of the fuel should not exceed 0.5 to prevent corrosion

Biofuels have been found to have a solvent property, so when switching from traditional marine heavy fuel to biofuel, d’Amico anticipated the risk of deposits in the fuel system being flushed out and that clogging of fuel filters might occur. To mitigate such risk, the storage, settling and service tanks were cleaned prior to bunkering B30 and specific changeover procedures were developed in accordance with the engine maker’s recommendations.

Avoid long storage periods – ideally no longer than 2-3 months

The main components of main engine (liners, pumps, pistons and injectors) were inspected before and after the trials to assess the conditions. They were found without any sign of deterioration or corrosion.

Bacteria and mould may grow if condensed water accumulates in biodiesel fuel. Microbial growth leads to excessive formation of sludge, clogged filters, and piping. To mitigate such risk, d’Amico adopted the following measures:

The protocol of fuel testing was amended adding a microbial test – all tests performed indicated no microbial contamination.

Regular draining of water from storage, settling and service tanks

In addition, tests for microbial growth were repeated every two weeks, along with the dosing of biocide if deemed necessary. However, no dosing was required during the trial period.

d’Amico recommend asking the biofuel supplier whether the feedstock (B100) complies with any quality standard, such as EN 14214: 2012.

Among the testing included in the ISO 8217 suite of tests, the most important are:

Water content – as low as possible to help prevent microbial growth

Pour point – to ensure correct storage and transfer temperatures are maintained

Ash content and potential abrasive components

Sulphur content – to ensure cylinder oil feed rates are set to optimum

In addition to the standard ISO 8217 suite of tests, the fuel testing protocol for B30 included:

Steel corrosion (to be carried out only if not done by the supplier)

Copper corrosion (to be carried out only if not provided by the supplier)

FAME content

Carbon, Hydrogen, Oxygen, Nitrogen (for emission purposes)

Stability at time of bunkering and after prolonged storage.

Acid value

Microbial test

The ultimate objective of the project was to certify the possible reduction of C02 emissions on a well-to-wake (well-to-propeller) basis.

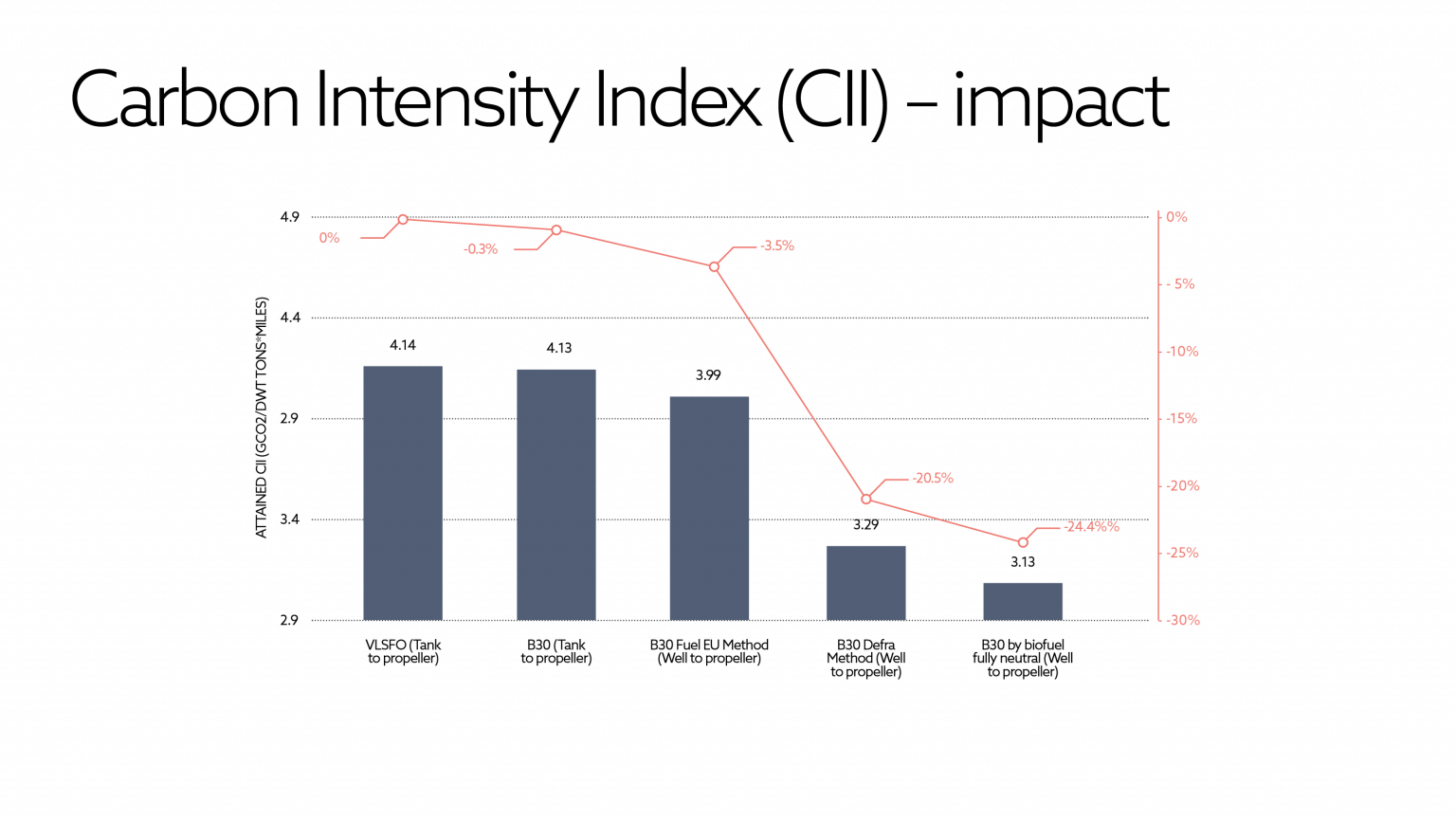

The team also wanted to see the effect on the Carbon Intensity Indicator (CII), which is a short-term measure adopted by the IMO, even though the legislation currently considers emissions on a tank-to-wake basis only.

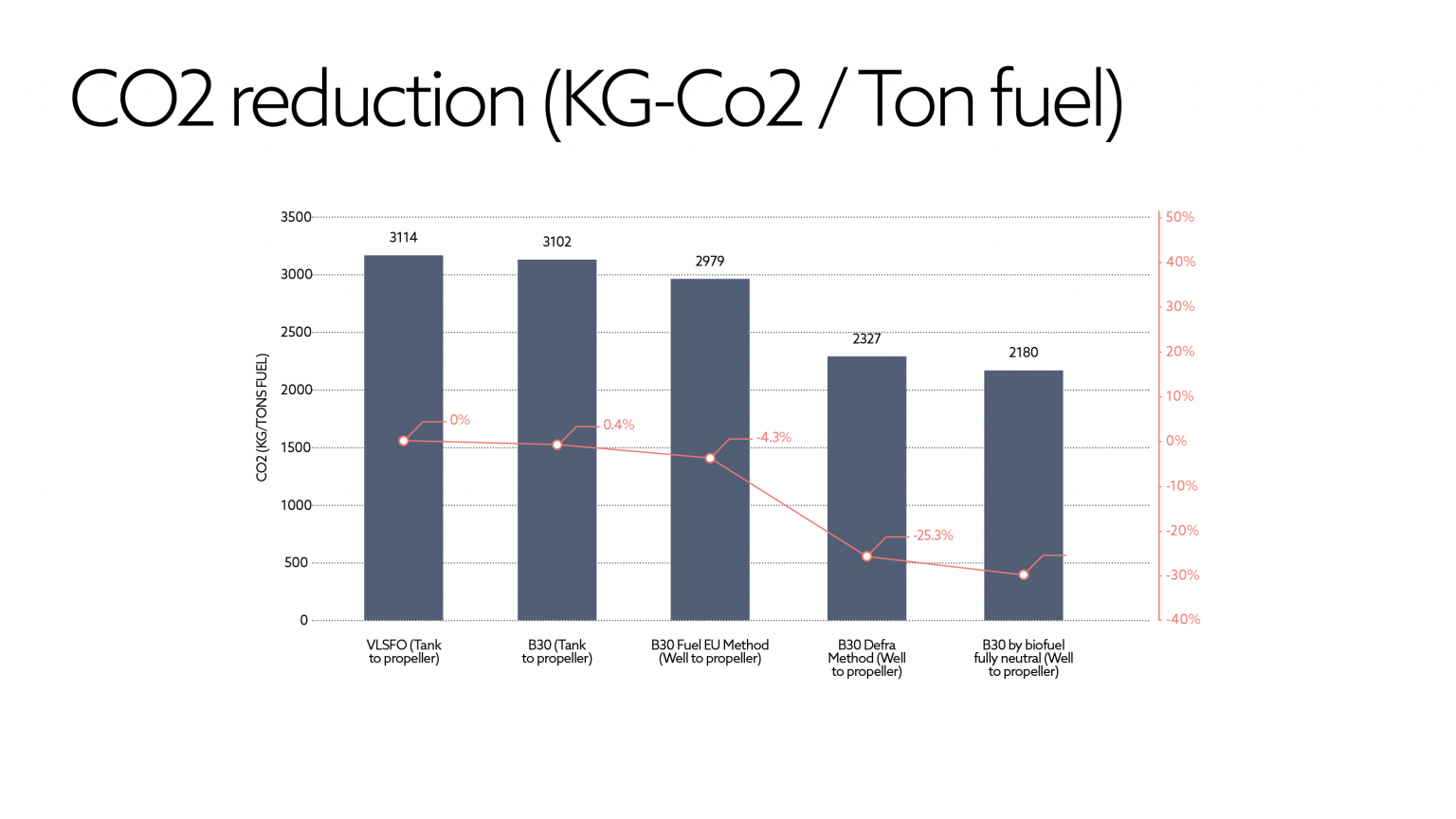

The impact on CO2 emissions and CII rating is summarised below:

CO2 reduction

The C02 emissions in terms of per tonne of fuel shows a different level of reduction basis on the method applied: -0,4% (tank to propeller basis); -4,3% (well to propeller basis) applying the Fuel Eu regulation; -25,3% (well to propeller basis) applying the Defra method; -30% (well to propeller basis) considering the feedstock fully neutral;

The C02 emissions in terms of per tonne of fuel shows a different level of reduction basis on the method applied: -0,4% (tank to propeller basis); -4,3% (well to propeller basis) applying the Fuel Eu regulation; -25,3% (well to propeller basis) applying the Defra method; -30% (well to propeller basis) considering the feedstock fully neutral;

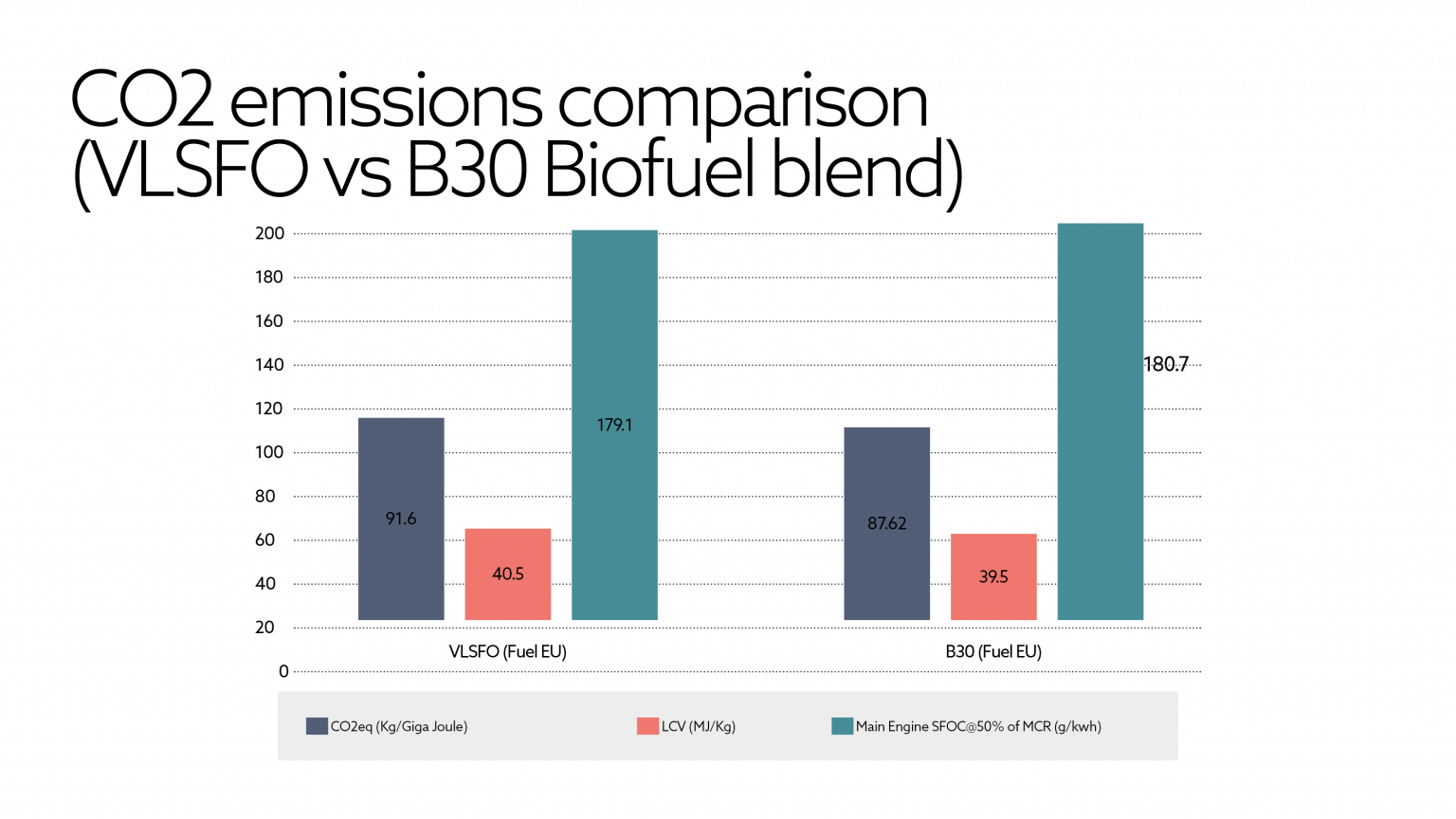

According the Fuel eu regulation, the C02eq emissions in terms of energy content (kg/Giga Joule) shows an improvement using the B30. The lower energy content of the B30 against the VLSFO was compensated by a very marginal increase in SFOC not as expected (only 1,6 g/kwh) resulting in an effective C02 reduction.

According the Fuel eu regulation, the C02eq emissions in terms of energy content (kg/Giga Joule) shows an improvement using the B30. The lower energy content of the B30 against the VLSFO was compensated by a very marginal increase in SFOC not as expected (only 1,6 g/kwh) resulting in an effective C02 reduction.

The Improvement effect on the CII was calculated using the DSC data provided for the 2020 and converting in Biofuel (B30) only the total consumption of VLSFO comsumed in 2020 (ie the ULSFO DM grade was not converted). The level of improvement depends by the methodology applied: -0,3% (tank to propeller basis); -3,5% (well to propeller basis) applying the Fuel Eu regulation; -20,5% (well to propeller basis) applying the Defra method; -24,4% (well to propeller basis) considering the feedstock fully neutral; *note: the calculation was done even if the WTW is not yet approved under the umbrella of IMO.

The Improvement effect on the CII was calculated using the DSC data provided for the 2020 and converting in Biofuel (B30) only the total consumption of VLSFO comsumed in 2020 (ie the ULSFO DM grade was not converted). The level of improvement depends by the methodology applied: -0,3% (tank to propeller basis); -3,5% (well to propeller basis) applying the Fuel Eu regulation; -20,5% (well to propeller basis) applying the Defra method; -24,4% (well to propeller basis) considering the feedstock fully neutral; *note: the calculation was done even if the WTW is not yet approved under the umbrella of IMO.

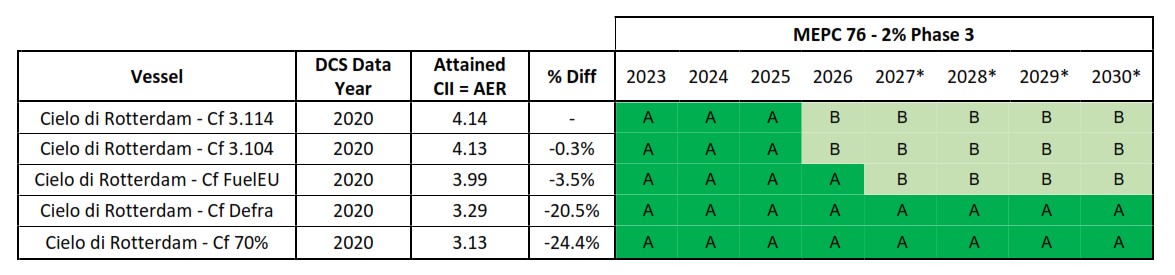

The calculations shows: No improvement on tank to propeller basis; + 1 Year in A rating (well to propeller basis) applying the Fuel Eu regulation; + 5 Years in A rating (well to propeller basis) applying either Defra or considering the feedstock fully neutral. *note: the calculation was done even if the WTW is not yet approved under the umbrella of IMO.

Trials were conducted under Flag dispensation permitted under MARPOL Annex VI, granting a six-month interim period within agreed parameters.

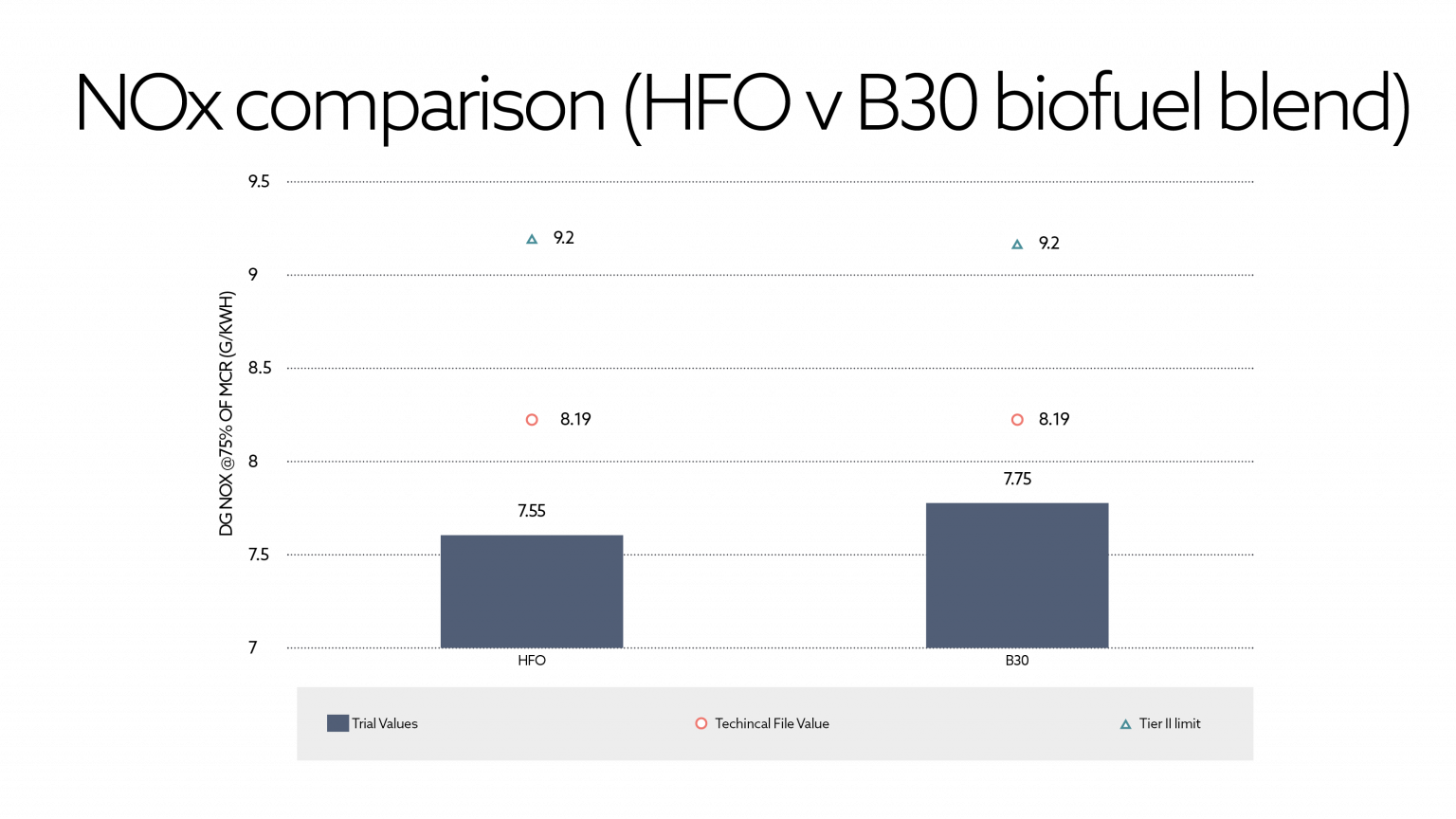

The NOx measurements during the trials found that the engine Tier II certification was not adversely affected.

NOx emissions related to the use of B30 in the diesel generators (DG’s) are approximately 2.6% above those generated by using VLSFO, but remain well below the maximum allowable limit (9.2g/kwh) for Tier II compliance. (Parent engine test bed is included for comparative purposes).

NOx emissions related to the use of B30 in the diesel generators (DG’s) are approximately 2.6% above those generated by using VLSFO, but remain well below the maximum allowable limit (9.2g/kwh) for Tier II compliance. (Parent engine test bed is included for comparative purposes).

Basis on these results, we have been certified by the Flag administration for all vessels equipped with same parent engines to operate permanently with blends up to B30 under “Equivalent arrangement accepted under Regulation 4 of Marpol Annex VI for the fuel oil quality under regulation 18.3.2 of MARPOL Annex VI”.

B30 was found to be easy to handle by the ship’s staff

Good storage capability, at least more than three months

Drop-in solution which means that biofuel blends can be used without modifications or specific engine requirements

NOx emissions remained within the Tier II allowable limit by calculation allowed by the NOx technical code for both the main engine and diesel generators

Positive effect on the CO2 reduction on well-to-wake (propeller) basis, marginal reduction when considered on tank-to-wake basis.

Positive effect on CII and class rating on well-to-wake (propeller) basis.

Viable solution to comply with Fuel EU regulation entering into force in 2025.

D’Amico Group’s sustainability route is aimed on focusing all projects and planning its activities that have an impact on its social, environmental, and economic dimensions within the framework of the UN’s Sustainable Development Goals (SDGs). There is also a concentration of effort in engaging and reinforcing the awareness of everyone inside the Group to the achievement of its sustainability goals.

Find out more about d’Amico Group here

With thanks to Antonia d’Amico, Group Sustainability Director, Cesare d’Api, Deputy Technical Director, Lorenzo d’Amico, Group Insurance Director, and Salvatore d’Amico, Fleet Director.

Antonia d’Amico, Group Sustainability Director |

Cesare d’Api, Deputy Technical Director |

Lorenzo d’Amico, Group Insurance Director |

Salvatore d’Amico, Fleet Director, d’Amico Group |